400-710mm PVC Pipe Extrusion Line e nang le enjene ea 92/188 110KW

400-710mm PVC Pipe Extrusion Line e nang le enjene ea 92/188 110KW

Moralo oa 400-710mm PVC Pipe:

Bakeng sa phala e kholo ea PVC, hangata e sebelisoa phala ea phepelo ea metsi ea indasteri. E sebelisoa haholo Saudi Arabia le linaheng tse bohareng ba bochabela. Bakeng sa phala e kholo ea bophara, matla a eona a ka fihla ho 800-1000kg / h. Re na le phihlelo e ngata ka phala e kholo ea PVC ea bophara. Bakeng sa mohala ona, re nka 92/188 110kw extruder ho netefatsa lebelo le tsitsitseng la extrusion. Thepa ea hlobo e nka 40Cr ka sesebelisoa sa sensor ea mocheso. Enjene ke Siemens-beide (khoebo e kopanetsoeng Chaena). E na le tanka ea "vacuum" e bolelele ba limithara tse 6 le lisebelisoa tse 'ne tsa ho hula popane.

Ts'ebetsong ea extrusion ea pipe ea pvc, lintlha tse lokelang ho ba hlokolosi

Nakong ea ts'ebetso ea extrusion ea liphaephe tsa CPVC (Chlorinated Polyvinyl Chloride), lintlha tse 'maloa li hloka tlhokomelo e hlokolosi ho netefatsa tlhahiso ea liphaephe tsa boleng bo phahameng. Lintlha tse ling tsa bohlokoa ke tsena:

1. **Ho Tšoaroa le ho Kopanya Lintho**:

- Etsa bonnete ba ho sebetsana le ho kopanya hantle ha resin ea CPVC le li-additives ho finyella ho hasana ho tšoanang le ho tsitsa ha thepa. Ho kopanya hantle ho bohlokoa bakeng sa ho boloka thepa e lakatsehang ea motsoako oa CPVC.

2. **Taolo ea Mocheso**:

- Sheba le ho laola mocheso oa extrusion ka hloko, kaha thepa ea CPVC e na le litlhoko tse khethehileng tsa mocheso bakeng sa ho sebetsa. Boloka mocheso ka har'a sebaka se khothalletsoang ho thibela ho senyeha ha thepa le ho netefatsa hore ho phalla ho nepahetseng ho qhibiliha.

3. **Moetso oa Screw and Configuration**:

- Sebelisa li-scruder screws tse etselitsoeng ka ho khetheha ho sebetsana le thepa ea CPVC. Moralo oa screw o lokela ho fana ka motsoako o lekaneng le homogenization ea ho qhibiliha ha o ntse o fokotsa mocheso oa ho kuta ho qoba ho senyeha ha thepa.

4. **Moqapi oa Die le Calibration**:

- Etsa bonnete ba hore moralo oa die o loketse bakeng sa extrusion ea pipe ea CPVC, e nang le litekanyo tse nepahetseng le geometry ho hlahisa liphaephe tse nang le botenya ba marako le bophara bo tsitsitseng. Lekanya lekhalo hantle ho fihlela boholo ba liphaephe tse tšoanang.

5. **Ho Pholisa le ho tima **:

- Kenya ts'ebetsong mekhoa e metle ea ho pholisa le ho tima ho pholisa phala e pharalletseng ea CPVC le ho beha boholo ba eona. Pholiso e nepahetseng ke ea bohlokoa bakeng sa ho thibela ho sotha kapa ho sotha ha pipe le ho netefatsa botsitso ba dimensional.

6. **Ho hula le ho Fetola Boholo**:

- Laola lebelo la ho hula le boholo ba phala ea CPVC ho fihlela boholo bo lakatsehang le pheletso ea bokaholimo. Ho hula le boholo bo nepahetseng ho netefatsa ho tšoana ka bophara ba phala le botenya ba lebota ho pholletsa le bolelele ba phala.

7. **Tekolo le Taolo ea Boleng**:

- Kenya ts'ebetsong mokhoa o pharaletseng oa ho hlahloba le oa ho laola boleng ho lemoha mefokolo leha e le efe kapa ho se lumellane ho liphaephe tsa CPVC tse extruded. Etsa litlhahlobo le liteko khafetsa ho netefatsa hore ho latela lipehelo le litekanyetso.

Ka ho laola lintlha tsena ka hloko nakong ea ts'ebetso ea extrusion, bahlahisi ba ka hlahisa liphaephe tsa boleng bo phahameng ba CPVC tse finyellang lintlha tse hlokahalang le litekanyetso tsa ts'ebetso.

Lintlha tsa mohala oa Extrusion:

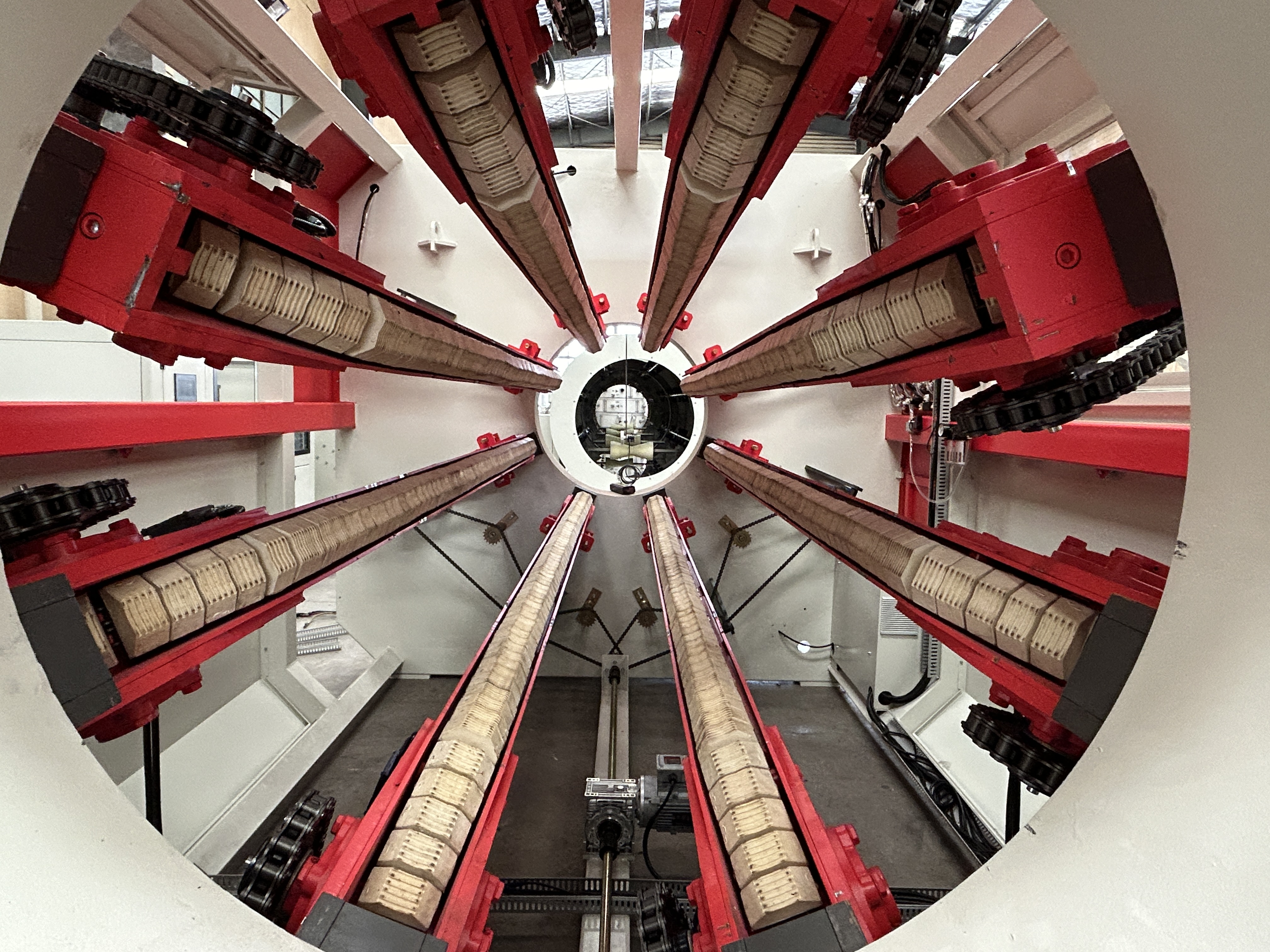

Mochini oa "twin screw extruder".

Li-extruder li entsoe ka likarolo tse holimo tsa marang-rang ho netefatsa botsitso ba tlhahiso, katleho le ho tšoarella ha mochini. Ka lebaka la tšobotsi ea thupa ea thepa ea PVC, re nka 110kw bakeng sa mohala oa extrusion ho netefatsa matla a sututsang. Ho sa le joalo screw le barrel ea rona e etselitsoe ho thibela litlhaku tse senyang haholo.

Vacuum calibration le tanka ea ho futhumatsa

Tanka ea calibration ea vacuum e amohela sebopeho sa likamore tse peli: vacuum calibration le likarolo tse pholileng. Bobeli ba tanka ea vacuum le tanka e pholileng ea ho fafatsa e sebelisa tšepe e sa hloekang ea 304. Sistimi e ntle ea vacuum e netefatsa boholo bo nepahetseng ba liphaephe. Re lelefatsa vacuum le tanka ea ho pholisa ho 8m. Ka ts'ebetso e telele ea ho pholile, phala ea PVC e ka pholile hantle 'me ea ba le bokaholimo bo betere.

Yuniti ea ho hula

Re amohela popane e mene mochining oa ho hula o etsa bonnete ba hore phala e hlahisoang e sebetsa ka mokhoa o tsitsitseng le e tsitsitseng. Likarolo tsa ho hula li ka etsa mofuta o hlophisitsoeng oa ho hula o ipapisitse le tlhokahalo e itseng ea tlhahiso ka ho lokisa taolo e akaretsang.

Setsi sa ho Seha

Encoder ea ho nepahala e phahameng e netefatsa bolelele bo nepahetseng le bo tsitsitseng ba ho itšeha. Ka sistimi ea taolo ea PLC, e ka khaoloa ka ts'ebetso ea matsoho ho latela ts'ebeliso e ikhethileng. Ka lebaka la tšobotsi e phahameng ea ho senya ea thepa ea PVC, libaka tsohle tsa lisebelisoa tsa ho itšeha li nka tšepe e sa hloekang 304. E tiisa nako ea bophelo ea ho sebetsa ea mochine oa ho itšeha.

ITEANYE LE RONA:

Pipe ea CPVC ke sehlahisoa se secha le se tummeng har'a liphaephe. Re na le phihlelo e ngata tšimong ea tlhahiso ea liphaephe tsa PVC, haeba u thahasella, pls ikopanye le 'na. Ke khona ho etsa tharollo ea mohatla le ho u romella livideo tse ngata tse sebetsang tsa tlhahiso ea liphaephe tsa PVC. Lebella ka thabo ho botsa hao.