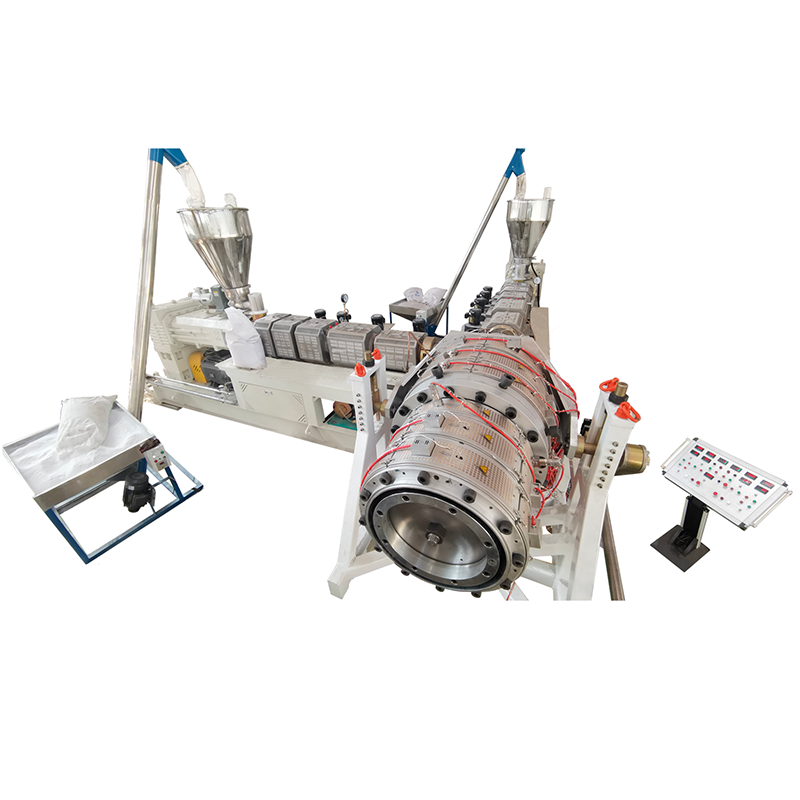

LB-PVC e kholo ea Diameter Pipe Extrusion Line

PVC phofo + additive - ho kopanya - thepa ea ho fepa - twin screw extruder - hlobo le calibrator - vacuum forming machine - spraying cooling machine - hull off machine - cuting machine - discharge rack kapa pipe belling machine.

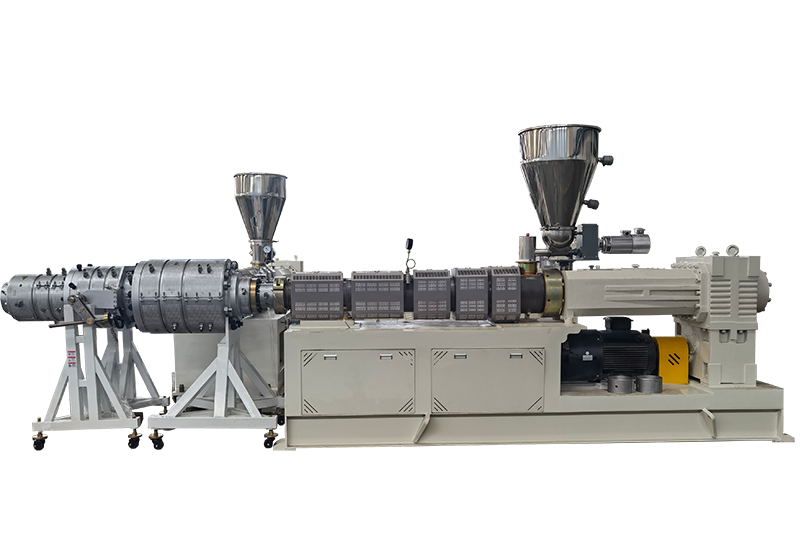

| Mohlala | 630 | 800 | 1000 |

| Bophahamo ba Lipeipi (mm) | 315-630 | 560-800 | 630-1000 |

| Screw Model | 80/156 | 92/188 | 92/188 |

| Ketso(kg) | 350 | 800 | 1100 |

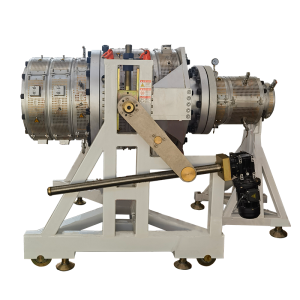

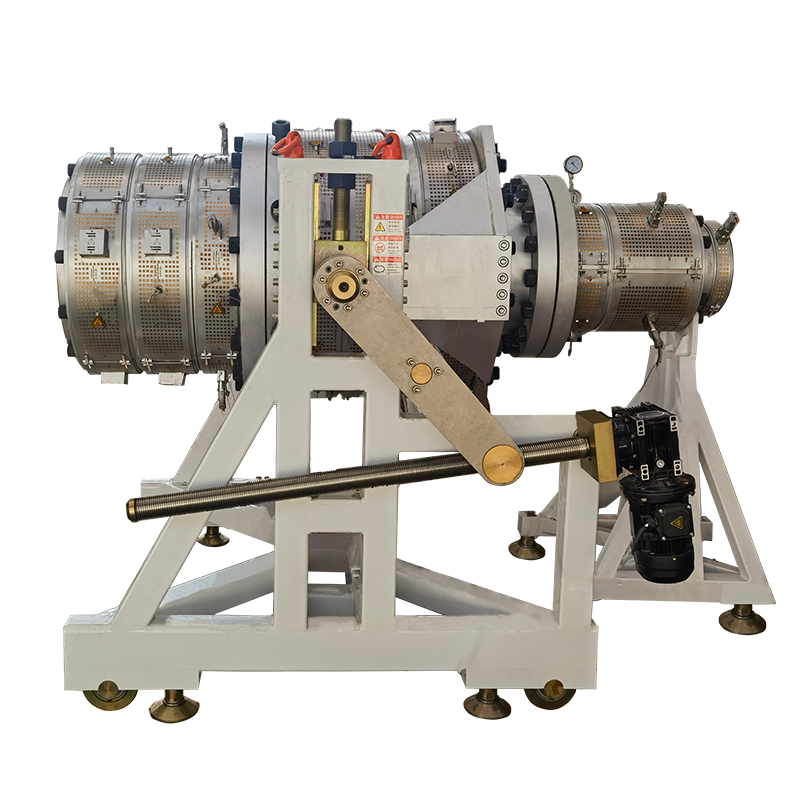

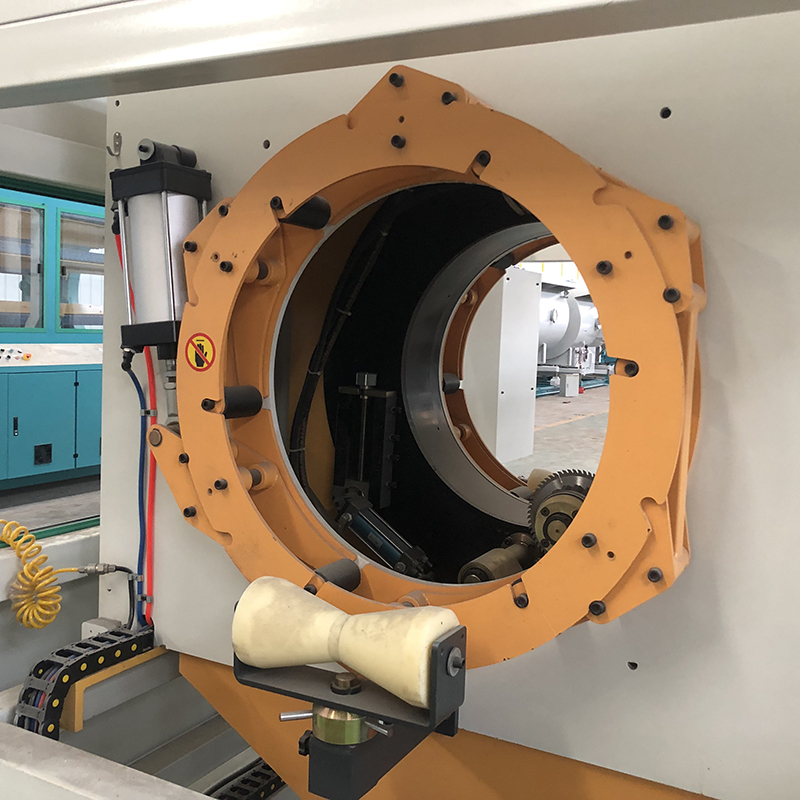

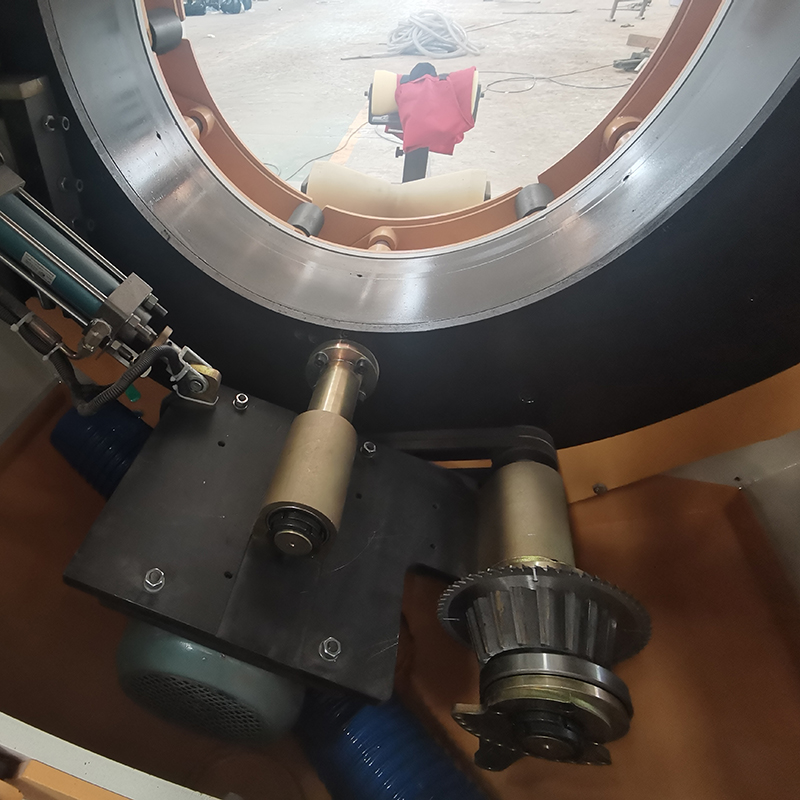

Conical Twin Screw Extruder

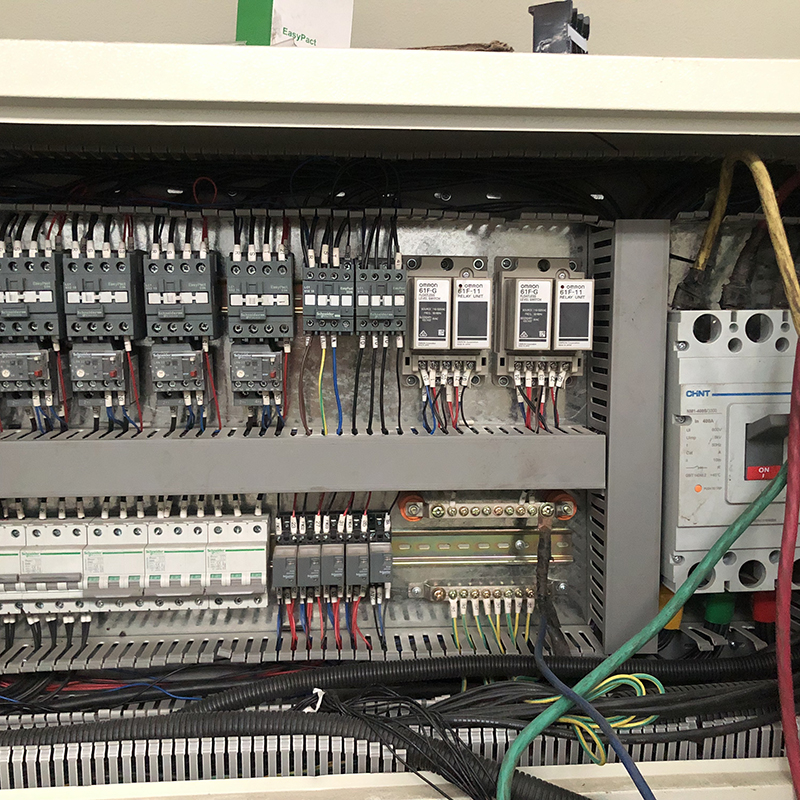

Re amohela Siemens e tloaelehileng ea koloi le lebelo le laoloang ke ABB inverter. Sistimi ea taolo e amohela taolo ea Siemens PLC kapa taolo ea konopo. Conical twin screw extruder ea mohala oa lipeipi e nka screw & barrel e sebetsang hantle haholo, lebokose la gear le nang le sistimi ea ho itlotsa. Ka touchscreen (ka boikgethelo) ke ho feta bohlale le tshebetso bonolo.

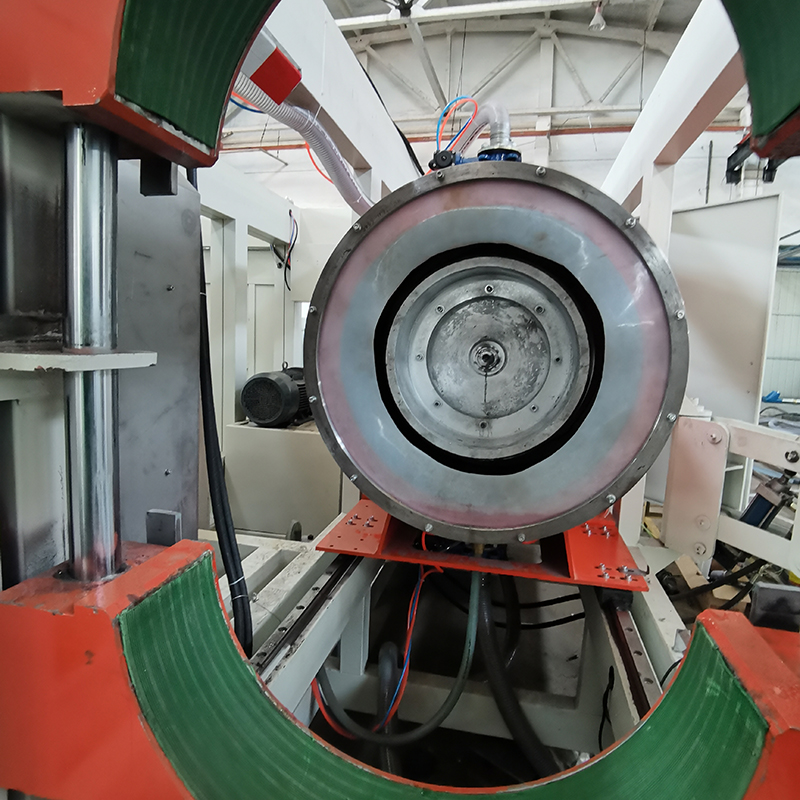

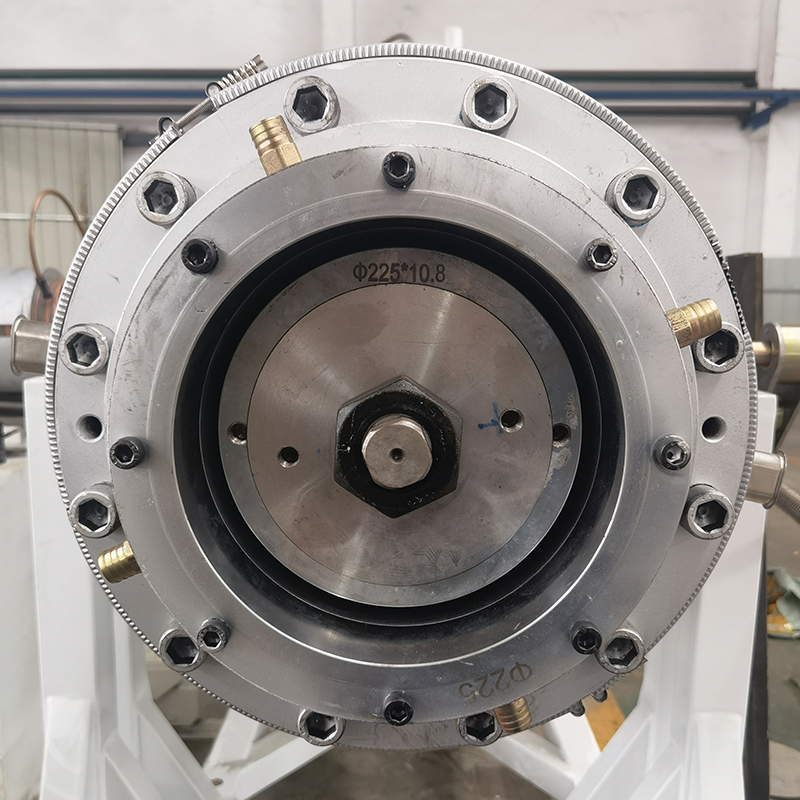

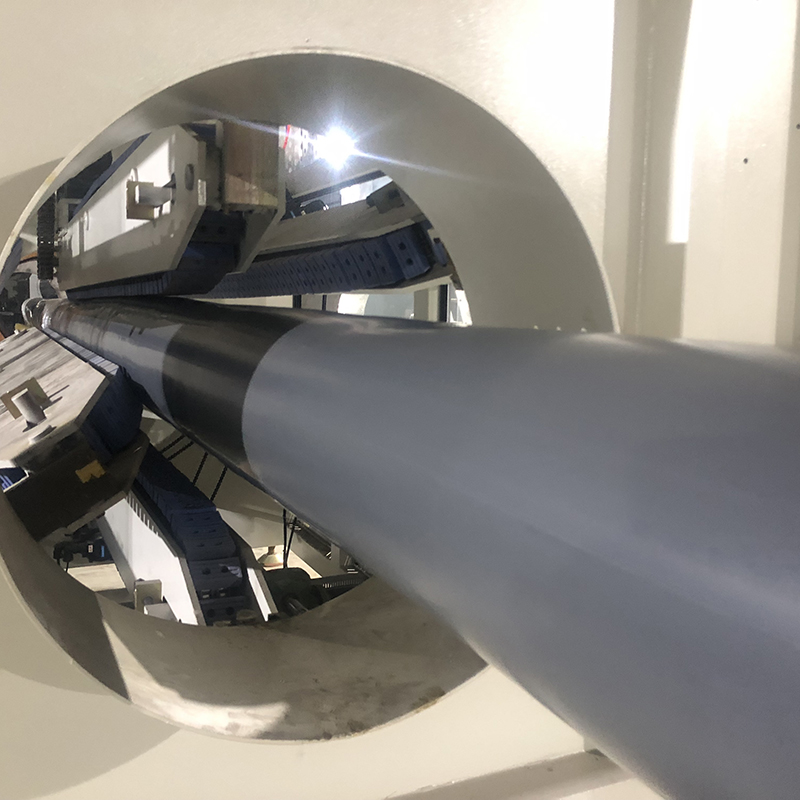

Hlobo

Mouta o na le moralo o pharalletseng oa mocha oa phallo ho netefatsa bokhoni bo phahameng ba extrusion le phello e ntle ea ho qhibiliha.

E entsoe le ho hlahlojoa ke moetsi ea nang le phihlelo. Taolo e ntlafalitsoeng ea mocheso le moralo oa mocha oa phallo o netefatsa taolo e nepahetseng ea mocheso oa ho qhibiliha.

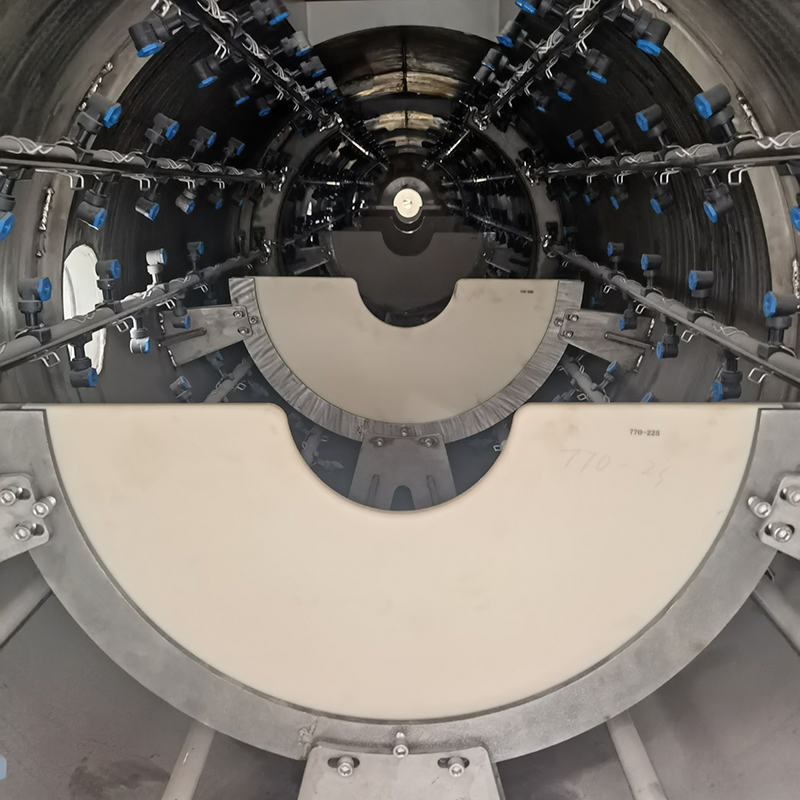

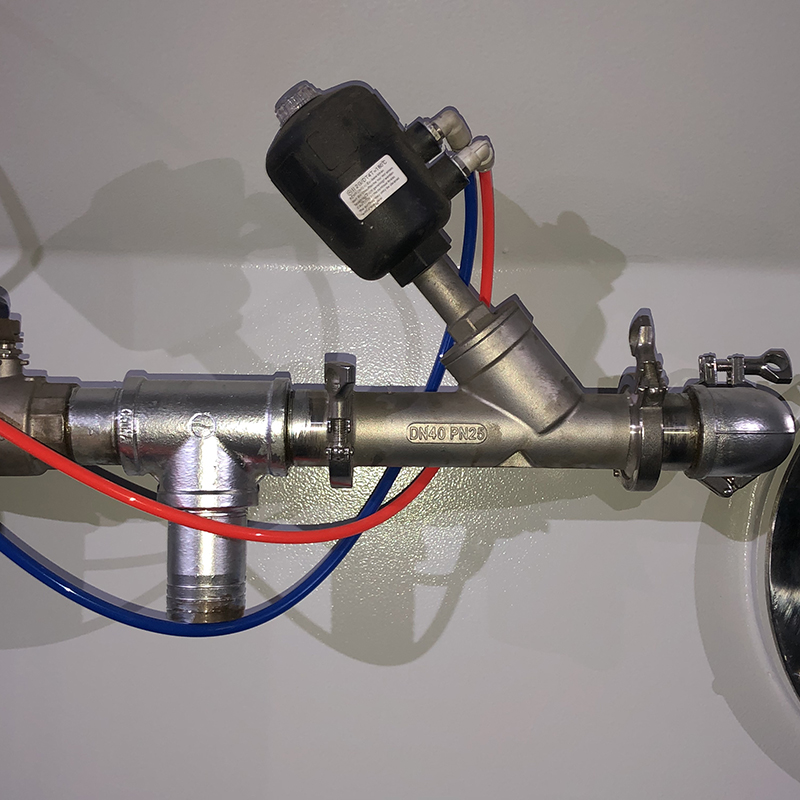

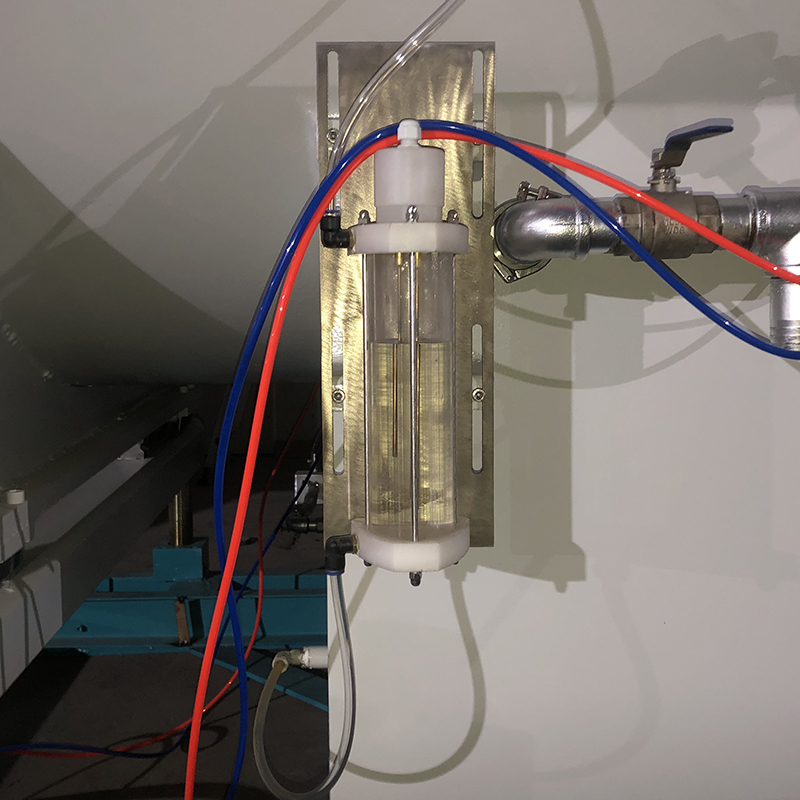

Setsi sa Vacuum Calibration & Cooling

Bobeli ba tanka ea vacuum le tanka e pholileng ea ho fafatsa e sebelisa tšepe e sa hloekang ea 304. Ka bolelele bo lekaneng ba ho fafatsa le ho pholisa ho tla ntlafatsa katleho ea ho pholisa; Sistimi ea taolo ea mocheso oa metsi ka boits'oaro e lokisoa ho latela mokhoa oa ho utloa mocheso.

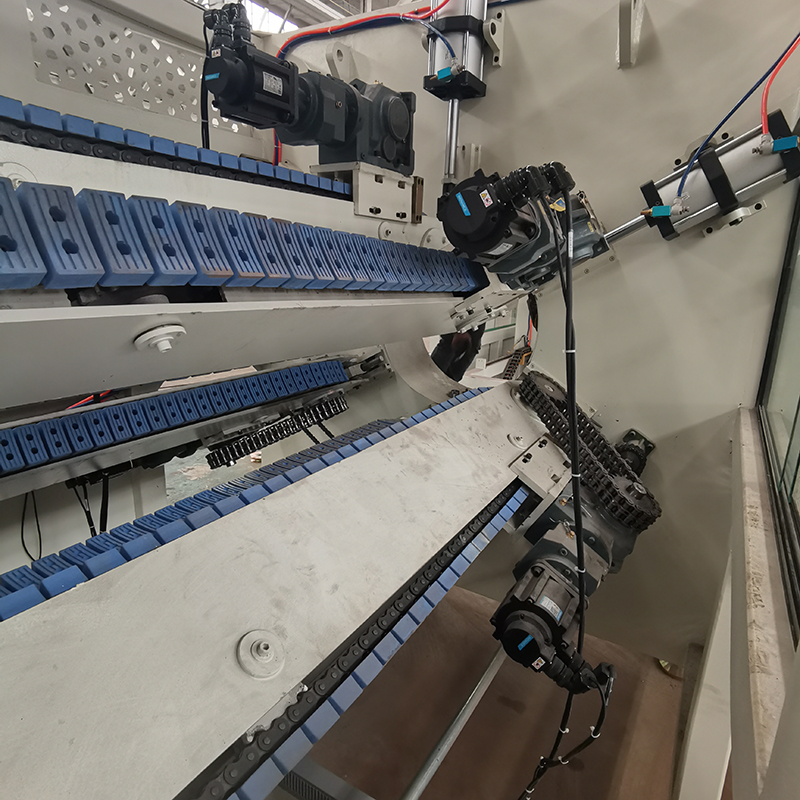

Mochini oa ho hula

Seboko se ts'eletseng mochining oa ho hula se etsa bonnete ba hore phala e hlahisoang e sebetsa ka mokhoa o tsitsitseng le o tsitsitseng. Likarolo tsa ho hula li ka etsa mofuta o hlophisitsoeng oa ho hula o ipapisitse le tlhokahalo e itseng ea tlhahiso ka ho lokisa taolo e akaretsang.

Motho ya sehang

Encoder ea ho nepahala e phahameng e netefatsa bolelele bo nepahetseng le bo tsitsitseng ba ho itšeha. Ka sistimi ea taolo ea PLC, e ka khaoloa ka ts'ebetso ea matsoho ho latela ts'ebeliso e ikhethileng.

Mochini oa tšepe

Mohala o na le sistimi ea socketing ea inthanete e sebetsang ka mokhoa o tsitsitseng le ka bohlale. Ho futhumatsa le ho tsidifatsa ha yona ho sebetsa hantle haholo mme ho nepahetse. Sokete ea peipi e chitja ebile e boreleli. E fana ka maemo a mabeli a futhumatsang bakeng sa ho bella ka nako ka lebelo le holimo.