Ka lebaka la litšoaneleho tsa thepa e tala ea cpvc, sekoti, moqomo, hlobo ea die, hul-off le moralo oa seha o fapana le mohala oa extrusion oa pipe ea upvc.

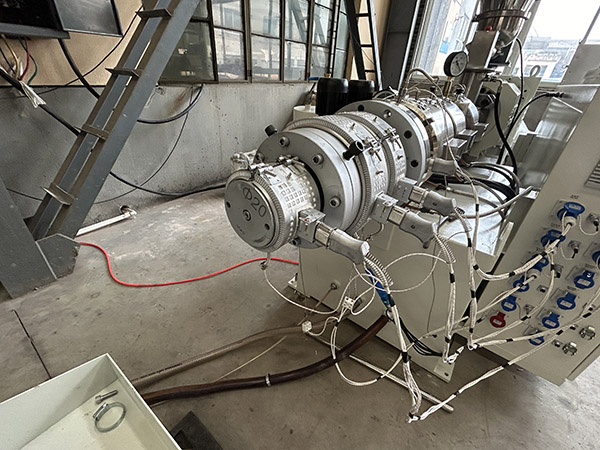

Kajeno ha re tsepamise maikutlo holim'a moralo oa hlobo oa screw and die.

Mokhoa oa ho fetola sebopeho sa screw bakeng sa extrusion ea pipe ea cpvc

Ho fetola sebopeho sa screw bakeng sa extrusion ea pipe ea CPVC ho kenyelletsa liphetoho ho ntlafatsa ho qhibiliha, ho kopanya le ho tsamaisa thepa ea CPVC. Mona ke lintlha tse ling tsa ho fetola sebopeho sa screw:

1. **Screw Geometry**:

- Fetola botebo le bophahamo ba sefofane: Ho fetola botebo le bophahamo ba sefofane ho ka ntlafatsa phetisetso le ho kopanya lisebelisoa tsa CPVC ka har'a sekoti.

2. **Compression Ratio**:

- Eketsa karo-karolelano ea khatello: Viscosity e phahameng ea CPVC e ka hloka litekanyo tse phahameng tsa compression ho hlahisa khatello e lekaneng le ho kuta bakeng sa ho qhibiliha le ho kopanya.

3. **Sekoaelo le Sekoaelo**:

- Sebelisa lisebelisoa kapa lirafshoa tse nang le khanyetso e matlafalitsoeng ea ho sesa le ho haneha ha kutu ho mamella mofuta o senyang le o senyang oa ts'ebetso ea CPVC.

- Nahana ka litlolo kapa liphekolo tse fokotsang khohlano le ho ntlafatsa thepa ea tokollo ho ntlafatsa phallo ea CPVC e qhibilihang le ho fokotsa ho roala ha screw.

4. **Screw Cooling/Heating**:

- Kenya ts'ebetsong libaka tsa ho futhumatsa / mohatsela haufi le "screw barrel" ho laola mocheso o qhibilihang le viscosity, haholo-holo libakeng tseo CPVC e ka bang le ho senyeha ha mocheso kapa mocheso o feteletseng.

5. **Screw Cooling**:

- Etsa bonnete ba hore pholile e nepahetseng ea screw ho boloka taolo ea mocheso le ho thibela ho futhumala ha CPVC ho qhibiliha, haholo-holo lits'ebetsong tse phahameng tsa extrusion.

Ka ho nahana ka lintlha tsena le ho etsa liphetoho tse nepahetseng moralong oa screw, bahlahisi ba ka ntlafatsa lits'ebetso tsa CPVC tsa extrusion ho fihlela boleng bo ts'oanang ba ho qhibiliha, homogeneity, le throughput.

Mokhoa oa ho fetola sebopeho sa die bakeng sa extrusion ea pipe ea cpvc

Ho fetola sebopeho sa "die" bakeng sa extrusion ea pipe ea CPVC ho kenyelletsa liphetoho bakeng sa ho amohela viscosity e phahameng ea CPVC le ho netefatsa extrusion e tšoanang.

1. **Die Heating/ Cooling**:

- Fetola libaka tse futhumatsang / tse batang: Lithempereichara tse phahameng tsa CPVC li ka hloka hore ho lokisoe mochini o futhumatsang / o pholileng ho boloka taolo e nepahetseng ea mocheso le ho thibela ho futhumala kapa ho bata.

2. **Die Materials and Coatings**:

- Nahana ka ho sebelisa lisebelisoa / liphahlo tse nang le khanyetso e phahameng ea mocheso: Lithempereichara tse phahameng tsa CPVC li ka hloka lisebelisoa tsa ho shoa kapa liphahlo tse ka mamellang mocheso o phahameng ntle le ho senyeha.

3. **Die Surface Finish**:

- Etsa bonnete ba hore sebaka se boreleli le se ts'oanang sa "fa": Sebaka se boreleli se thusa ho fokotsa likhohlano le matla a ho kuta, ho fokotsa kotsi ea ho qhibiliha ho qhibiliha le ho netefatsa hore ho na le extrusion e tšoanang.

4. **Lisebelisoa tsa ho Laola Phallo**:

- Kenyelletsa lisebelisoa tsa taolo ea phallo, joalo ka tse kentsoeng kapa lithibelo, ho ntlafatsa phallo ea phallo le ho ts'oana ha khatello ho profaele ea die, haholo ho li-geometries tse rarahaneng.

5. **Die Design Simulation**:

- Sebelisa software ea ketsiso ea die design ho sekaseka boits'oaro ba phallo, kabo ea khatello, le boemo ba mocheso ka har'a lefu. Sena se lumella tlhahlobo ea sebele ea liphetoho tse fapaneng tsa lefu ho ntlafatsa ts'ebetso pele ho ts'ebetso ea 'mele.

Ka ho nahana ka lintlha tsena le ho etsa liphetoho tse nepahetseng ho moralo oa lefu, bahlahisi ba ka ntlafatsa lits'ebetso tsa extrusion tsa pipe ea CPVC ho fihlela boleng bo tsitsitseng le ho nepahala ha boholo.

Ts'ebetsong ea extrusion ea pipe ea cpvc, lintlha tse lokelang ho ba hlokolosi

Nakong ea ts'ebetso ea extrusion ea liphaephe tsa CPVC (Chlorinated Polyvinyl Chloride), lintlha tse 'maloa li hloka tlhokomelo e hlokolosi ho netefatsa tlhahiso ea liphaephe tsa boleng bo phahameng. Lintlha tse ling tsa bohlokoa ke tsena:

1. **Ho Tšoaroa le ho Kopanya Lintho**:

- Etsa bonnete ba ho sebetsana le ho kopanya hantle ha resin ea CPVC le li-additives ho finyella ho hasana ho tšoanang le ho tsitsa ha thepa. Ho kopanya hantle ho bohlokoa bakeng sa ho boloka thepa e lakatsehang ea motsoako oa CPVC.

2. **Taolo ea Mocheso**:

- Sheba le ho laola mocheso oa extrusion ka hloko, kaha thepa ea CPVC e na le litlhoko tse khethehileng tsa mocheso bakeng sa ho sebetsa. Boloka mocheso ka har'a sebaka se khothalletsoang ho thibela ho senyeha ha thepa le ho netefatsa hore ho phalla ho nepahetseng ho qhibiliha.

3. **Moetso oa Screw and Configuration**:

- Sebelisa li-scruder screws tse etselitsoeng ka ho khetheha ho sebetsana le thepa ea CPVC. Moralo oa screw o lokela ho fana ka motsoako o lekaneng le homogenization ea ho qhibiliha ha o ntse o fokotsa mocheso oa ho kuta ho qoba ho senyeha ha thepa.

4. **Moqapi oa Die le Calibration**:

- Etsa bonnete ba hore moralo oa die o loketse bakeng sa extrusion ea pipe ea CPVC, e nang le litekanyo tse nepahetseng le geometry ho hlahisa liphaephe tse nang le botenya ba marako le bophara bo tsitsitseng. Lekanya lekhalo hantle ho fihlela boholo ba liphaephe tse tšoanang.

5. **Ho Pholisa le ho tima **:

- Kenya ts'ebetsong mekhoa e metle ea ho pholisa le ho tima ho pholisa phala e pharalletseng ea CPVC le ho beha boholo ba eona. Pholiso e nepahetseng ke ea bohlokoa bakeng sa ho thibela ho sotha kapa ho sotha ha pipe le ho netefatsa botsitso ba dimensional.

6. **Ho hula le ho Fetola Boholo**:

- Laola lebelo la ho hula le boholo ba phala ea CPVC ho fihlela boholo bo lakatsehang le pheletso ea bokaholimo. Ho hula le boholo bo nepahetseng ho netefatsa ho tšoana ka bophara ba phala le botenya ba lebota ho pholletsa le bolelele ba phala.

7. **Tekolo le Taolo ea Boleng**:

- Kenya ts'ebetsong mokhoa o pharaletseng oa ho hlahloba le oa ho laola boleng ho lemoha mefokolo leha e le efe kapa ho se lumellane ho liphaephe tsa CPVC tse extruded. Etsa litlhahlobo le liteko khafetsa ho netefatsa hore ho latela lipehelo le litekanyetso.

Ka ho laola lintlha tsena ka hloko nakong ea ts'ebetso ea extrusion, bahlahisi ba ka hlahisa liphaephe tsa boleng bo phahameng ba CPVC tse finyellang lintlha tse hlokahalang le litekanyetso tsa ts'ebetso.

Nako ea poso: Apr-02-2024