01 Melao-motheo ea mochini

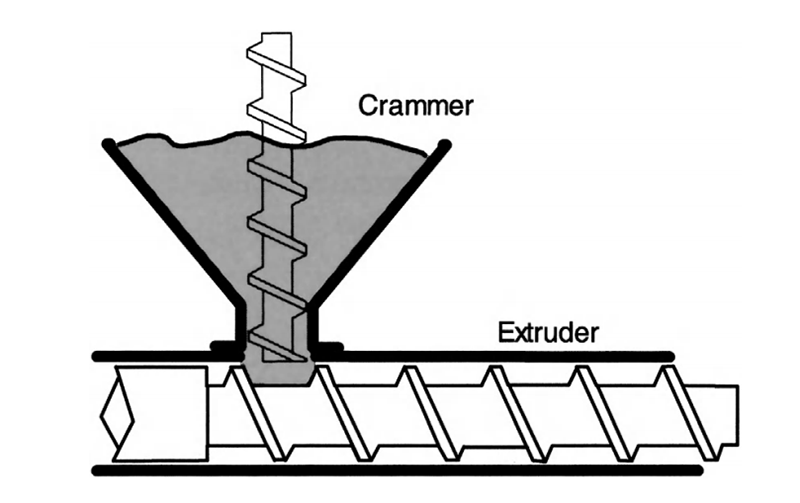

Mochine oa mantlha oa extrusion o bonolo - sekoti se thinyetsa ka har'a silinda ebe se sutumelletsa polasetiki pele. The screw ha e le hantle ke bevel kapa ramp e pota-potileng lera e bohareng. Sepheo ke ho eketsa khatello e le ho hlōla khanyetso e kholoanyane. Tabeng ea extruder, ho na le mefuta e 3 ea khanyetso e lokelang ho hlōloa: khohlano ea likaroloana tse tiileng (fepa) leboteng la cylinder le ho ferekana pakeng tsa bona ha screw e chencha ka makhetlo a seng makae (feed zone); ho khomarela ho qhibiliha leboteng la silinda; Ho hanyetsa ha ho qhibiliha ho thepa ea eona ea ka hare ha e sutumetsoa pele.

Li-screw tse ngata ke likhoele tse ka letsohong le letona, joalo ka tse sebelisoang ho rala mapolanka le metjhini. Haeba li shejoa ka morao, li thinyetsa ka nqa e ’ngoe hobane li etsa sohle se matleng a tsona ho bilikisa moqomo ka morao. Likarolong tse ling tsa li-scruder tse peli, li-screw tse peli li pota-pota ka lisilindara tse peli ebe li tšela tse ling, kahoo e 'ngoe e tlameha ho shebana le ho le letona ha e' ngoe e shebane le le letšehali. Li-screws tse ling tse peli tse lomang, li-screw tse peli li potoloha ka lehlakoreng le le leng, kahoo li tlameha ho ba le mokhoa o tšoanang. Leha ho le joalo, ho sa tsotellehe hore na boemo ke bofe, ho na le li-thrust bearings tse monyang matla a khutlelang morao, ’me molao-motheo oa Newton o ntse o sebetsa.

02 Molao-motheo oa mocheso

Li-plastics tse fetisitsoeng ke thermoplastics-li qhibiliha ha li futhumala ebe lia tiea hape ha li pholile. Mocheso oa polasetiki e qhibilihang o tsoa hokae? Feed preheating le cylinder/die heaters li ka sebetsa 'me tsa bohlokoa ha li qala, empa matla a kenyang enjine-mocheso o fokang o hlahisoang ka moqomong ha enjene e fetola sekoere khahlanong le khanyetso ea ho qhibiliha ha viscous-ke mohloli oa bohlokoa ka ho fetisisa oa mocheso. bakeng sa li-plastiki tsohle, ntle le lisebelisoa tse nyenyane, li-screws tse lebelo le tlaase, li-plastiki tse qhibilihang ka mocheso o phahameng, le lisebelisoa tsa ho roala ka extrusion.

Bakeng sa lits'ebetso tse ling kaofela, ho bohlokoa ho hlokomela hore heater ea cartridge ha se mohloli o ka sehloohong oa mocheso o sebetsang 'me ka hona o na le phello e fokolang ho extrusion ho feta kamoo re neng re ka lebella. Thempereichara e ka morao ea silinda e ntse e ka ba ea bohlokoa hobane e ama sekhahla seo lintho tse tiileng li tsamaisoang ka tsona ka meshing kapa ho fepa. Thempereichara ea die le hlobo hangata e lokela ho ba mocheso o lakatsehang oa ho qhibiliha kapa haufi le eona, ntle le haeba li sebelisetsoa morero o itseng joalo ka varnishing, kabo ea mokelikeli, kapa taolo ea khatello.

03 Molao-motheo oa ho fokotsa lebelo

Ho li-extruder tse ngata, phetoho ea lebelo la screw e finyelloa ka ho fetola lebelo la enjene. Hangata enjene e fetoha ka lebelo le felletseng la 1750rpm, empa e potlakile haholo bakeng sa screw e le 'ngoe ea extruder. Haeba e pota-potiloe ka lebelo le potlakileng joalo, ho hlahisoa mocheso o mongata haholo, 'me nako ea ho lula ea polasetiki e khutšoanyane haholo ho lokisetsa seaparo sa junifomo, se tsositsoeng hantle. Maemo a tloaelehileng a theolelo a pakeng tsa 10:1 le 20:1. Mokhahlelo oa pele o ka ba o hlophisitsoeng kapa oa pulley, empa mohato oa bobeli o lebisitsoe 'me screw e behiloe bohareng ba gear e kholo ea ho qetela.

Mechineng e meng e tsamaeang butle (e kang li-screws tse peli tsa UPVC), ho ka 'na ha e-ba le mekhahlelo ea 3 ea ho fokotsa lebelo' me lebelo le leholo le ka ba tlaase ho 30 rpm kapa ka tlase (karolelano ho 60: 1). Ka lehlakoreng le leng, li-screws tse telele tsa mafahla bakeng sa ho sisinyeha li ka matha ka 600rpm kapa ka potlako, kahoo ho hlokahala sekhahla se tlaase haholo sa ho theoha hammoho le ho bata haholo.

Ka linako tse ling sekhahla sa ho theoha ha se lumellane le mosebetsi-matla a mangata a sala a sa sebelisoe-'me ho ka khoneha ho eketsa pulley e behiloeng pakeng tsa motlakase le mohato oa pele oa ho theola lebelo o fetolang lebelo le leholo. Sena se ka eketsa lebelo la screw ho feta moeli o fetileng kapa se fokotsa lebelo le phahameng, ho lumella sistimi ho sebetsa ka liperesente tse kholo tsa lebelo le phahameng. Sena se eketsa matla a teng, se fokotsa matla le ho qoba mathata a koloi. Maemong ana ka bobeli, tlhahiso e ka eketseha ho latela thepa le litlhoko tsa eona tsa ho pholisa.

Tobetsa lebitso:

Qing Hu

Langbo Machinery Co.,Ltd

No.99 Lefeng Road

215624 Leyu Town Zhangjiagang Jiangsu

Mohala: +86 58578311

EMail: info@langbochina.com

Websaeteng: www.langbochina.com

Nako ea poso: Jan-17-2023