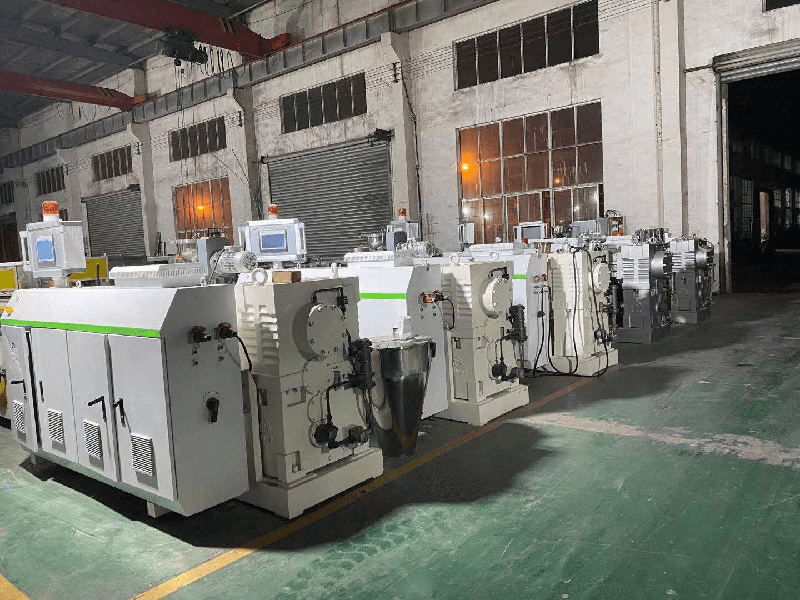

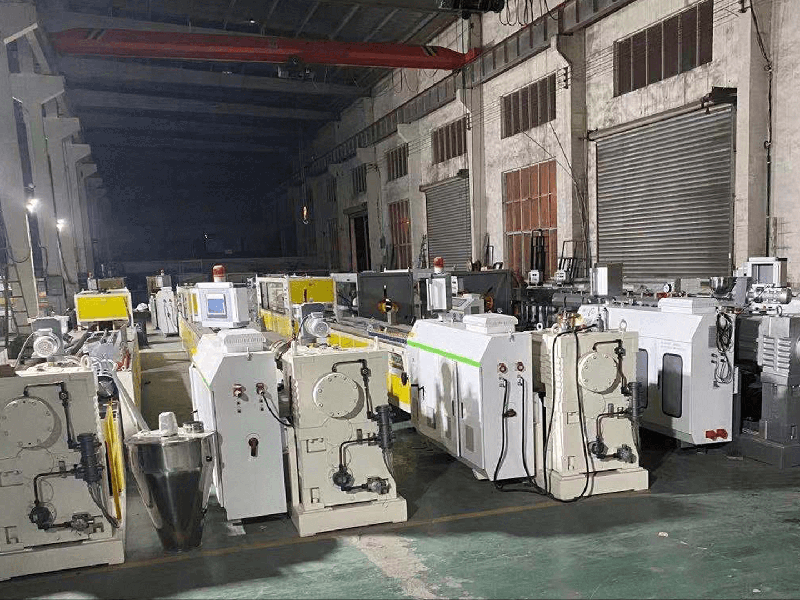

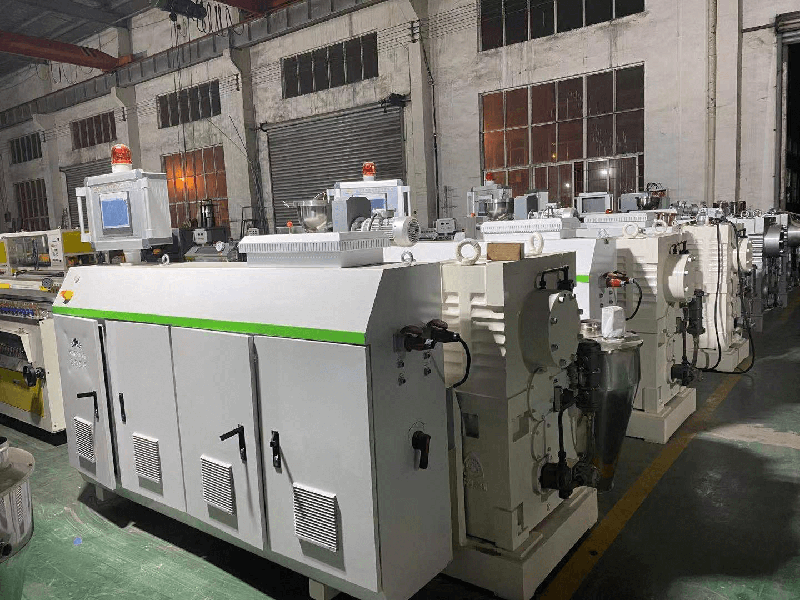

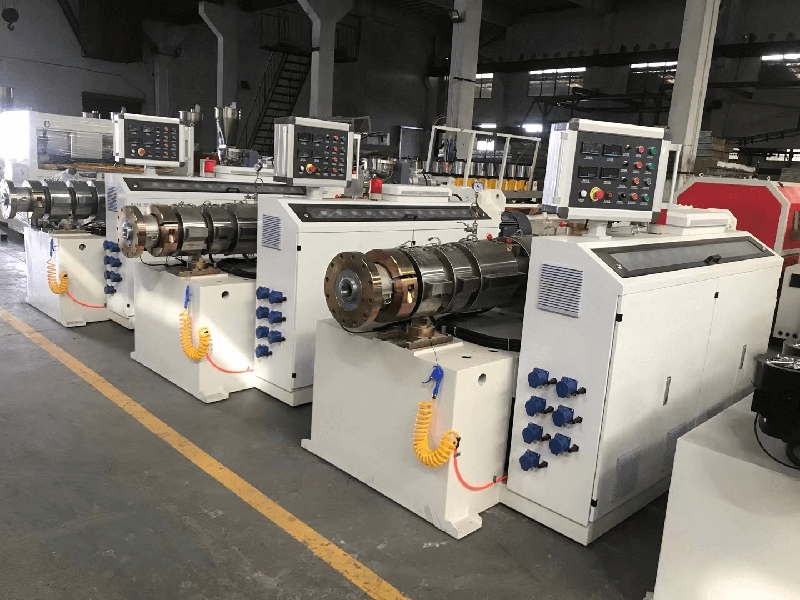

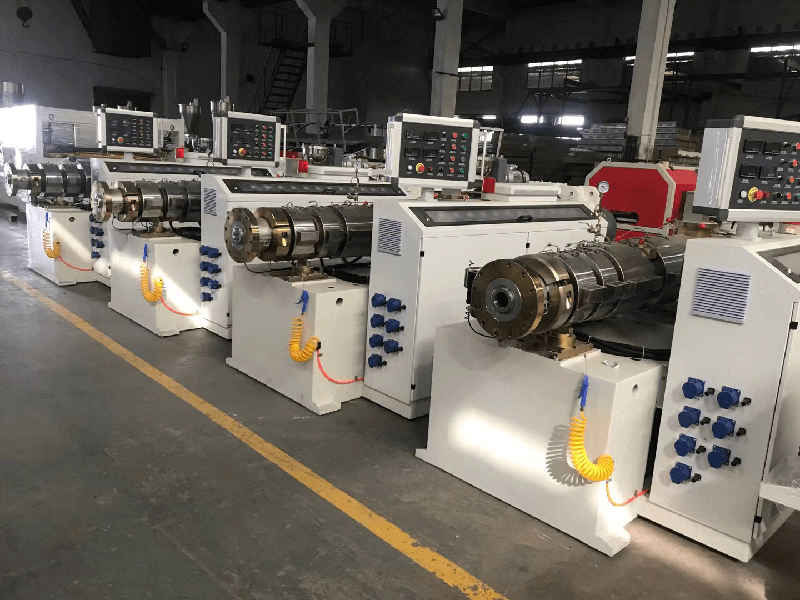

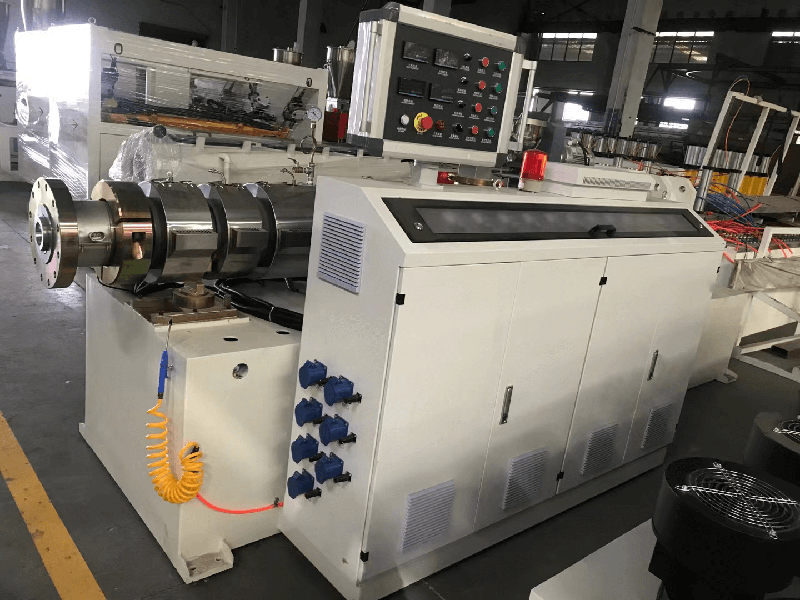

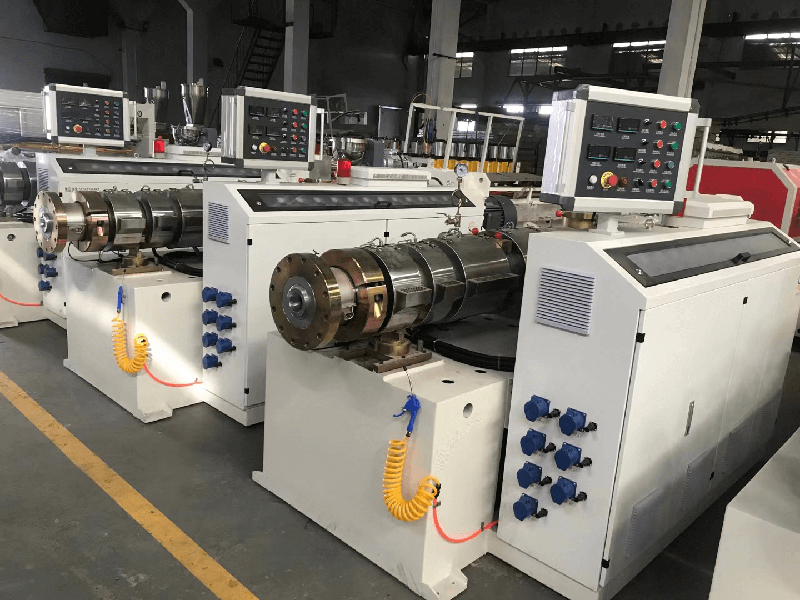

LB-PLC laola High Capacity PVC Pipe Production Line

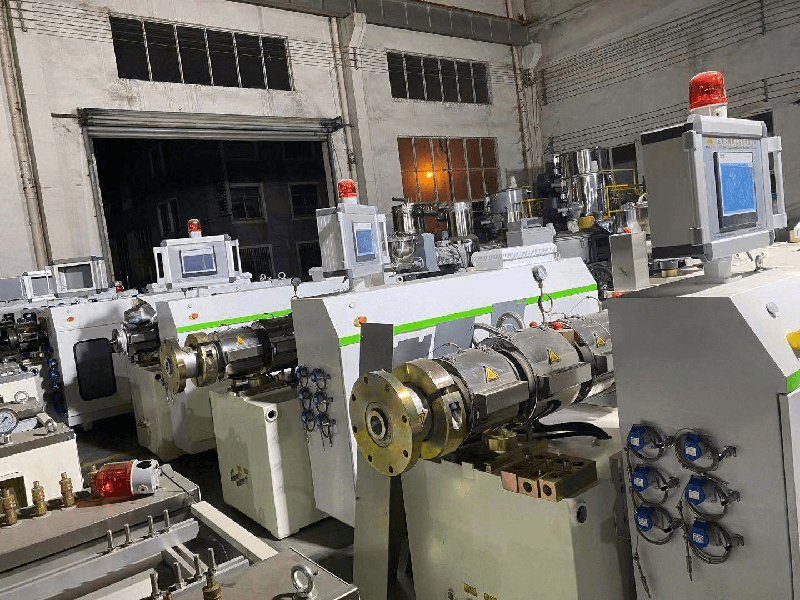

1. Mohlala SJZ letoto la conical mafahla-screw extruder ke mofuta oa thepa e khethehileng bakeng sa extruding PVC motsoako. Ka mefuta e fapaneng ea hlobo le metjhini e thusang, e ka hlahisa mefuta eohle ea phala ea polasetiki ea PVC, profil, lisebelisoa tsa poleiti, lisebelisoa tsa lakane, lisebelisoa tsa bar, le granulation.

2. Li-screws tsa mafahla a conical li sebelisitse mokhoa oa ho pholisa oli. Moqomo o pholile ka mokhoa o khethehileng oa ho pholisa moea.

3. Sistimi ea conical twin-screw extruder e sebelisitse taolo e khethehileng ea komporo. Ho ea ka litlhoko tsa bareki, sebopeho se nang le kahlolo e molemo ka ho fetisisa sa conical twin-screw se ka etsoa e le hore se fihlele ts'ebetso e ntle ka ho fetisisa ea polasetiki le boleng ba thepa.

4. The conical twin-screw e entsoe ka ho nepahala ho phahameng ho khethehileng digital screw miller; thepa extruding e ka lumellana haholo. E hlahisitse pele mokhoa o tsoetseng pele oa ho hlahisa sekoti se nang le sekontiri se feto-fetohang le botebo, e le hore thepa e ka kuta butle le ho sehoa.

5. Lebokose la kabo le entsoe ka ho khetheha, ho hula matla ho romelloa ka ho feletseng, 'me nako ea bophelo ea koloi e ka lelefatsoa. E ka mamella khatello e kholo ea extruding.

6. Mokhoa oa motlakase o sebelisitse haholo-holo likarolo tse tsoang linaheng tse ling, o na le lisebelisoa tse ngata tsa alamo, 'me ho na le mathata a seng makae a ka felisoang habonolo. Sistimi ea pholileng e sebelisitse moralo o ikhethileng, sebaka sa tlhahiso ea mocheso se a atolosoa, pholiso e potlakile, 'me mamello ea taolo ea mocheso e ka ba ±1 degree.

| MOHLALA | PIPE DIAMETER(MM) | MOHLALA EXTRUDER | MATLA A MOSEBETSI (KW) |

| LB-63A | 16-63 | SJSZ51/105 | 22 AC |

| LB-63B | 16-63(PIPE HAABELI) | SJSZ65/132 | 37 AC |

| LB-160 | 50-160 | SJSZ65/132 | 37 AC |

| LB-250A | 63-250 | SJSZ65/132 | 37 AC |

| LB-250B | 63-250 | SJSZ80/156 | 55 AC |

| LB-315 | 110-315 | SJSZ80/156 | 55 AC |

| LB-630 | 315-630 | SJSZ92/188 | 110 DC |

Motsoaki

Ka moralo o ikhethileng oa mixer, ho itšehla thajana ha thepa e tala hoa fokotseha. E thusa ho sebetsa hantle ha tšebeliso ea matla. Sesebelisoa sa Vacuum suction se na le lerata le tlase ebile ha se na lerole.

Mochini oa "twin screw extruder".

Li-extruder li entsoe ka likarolo tse holimo tsa marang-rang ho netefatsa botsitso ba tlhahiso, katleho le ho tšoarella ha mochini. Moralo oa rona oa conical screw extruder o sebetsana le lisebelisoa tse tala tse netefatsang motsoako o ts'oanang, plastification e betere le bokhoni ba ho fetisa.

Vacuum Calibration & Cooling

Tanka ea calibration ea vacuum e amohela sebopeho sa likamore tse peli: vacuum calibration le likarolo tse pholileng. Bobeli ba tanka ea vacuum le tanka e pholileng ea ho fafatsa e sebelisa tšepe e sa hloekang ea 304. Sistimi e ntle ea vacuum e netefatsa boholo bo nepahetseng ba liphaephe.

Yuniti ea ho hula

Popane e meraro mochining oa ho hula o etsa bonnete ba hore phala e hlahisoang e sebetsa ka mokhoa o tsitsitseng le e tsitsitseng. Likarolo tsa ho hula li ka etsa mofuta o hlophisitsoeng oa ho hula o ipapisitse le tlhokahalo e itseng ea tlhahiso ka ho lokisa taolo e akaretsang.

Setsi sa ho Seha

Encoder ea ho nepahala e phahameng e netefatsa bolelele bo nepahetseng le bo tsitsitseng ba ho itšeha. Ka sistimi ea taolo ea PLC, e ka khaoloa ka ts'ebetso ea matsoho ho latela ts'ebeliso e ikhethileng.