LB-WaterRing Cutting Granulating Line

| Mohlala | LBWR-80 | LBWR-100 | LBWR-140 | LBWR-160 | LBWR-180 |

| Screw Model | 80/38:1 | 100/38:1 | 140/38:1 | 160/38:1 | 180/38:1 |

| Ketso(kg) | 120-160 | 260-400 | 450-600 | 600-800 | 800-1000 |

| Matla a Enjene(kW) | 55 | 110 | 200 | 250 | 315 |

Automatic Conveyor

Mokhanni oa AC o laoloang ke conveyor motor

Metal detector e le khetho e laolang ketso ea conveyor ka temoso le ho emisa.

Sesebelisoa sa phepelo se laoloang ke lebelo la ho fepa la AC Driver se ipapisitse le matla a nako ea nnete a komporo.

Compactor ea ho haha

Stator le rotor seha thepa e tala.Khohlano ea likhechana tsa lintho tse bonahalang e eketsa mocheso ho compactor.Mocheso o phahameng o thusa thepa ka ho fokotsa mongobo le karohano ea lerōle ho tloha ho likhechana tsa thepa.Sesebelisoa sa Degassing se tlohella mongobo ho tsoa ho komporo mme se fane ka thepa ka boemo bo betere bakeng sa ts'ebetso e tsoelang pele

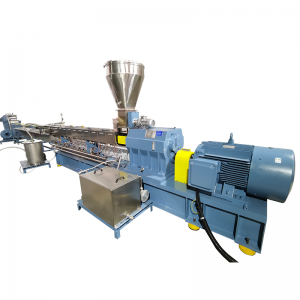

Sekurufu se le seng sa Extruder

Kopo e ipakile e tšoana le screw le motor bakeng sa tlhahiso e tsitsitseng le nako e telele ea ts'ebeletso.Lisebelisoa tsa boleng bo holimo tsa screw le Bi-metal process bakeng sa extrusion e sebetsang hantle le nako e telele ea ho sebetsa.

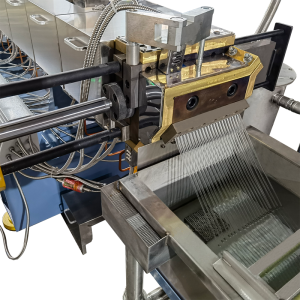

Sefahla sa Hydraulic Melt Mold

Lits'oants'o tsa tšepe tsa 304 tse nang le mesh ea boholo bo hlophisitsoeng

Sefate sa hydraulic plate kapa cylinder filter se fumaneha.

Mofuthu oa bronze bakeng sa katleho e phahameng ea ho futhumatsa

Ho ikhethela ho fetola sistimi e felletseng ea skrineng e felletseng

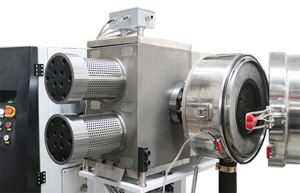

Metsi-Ring Granulator

Khatello ea ho kopana pakeng tsa thipa ea rotary le sefahleho sa sefahleho se behoa leihlo bakeng sa nako e telele ea ho itšeha le boleng bo phahameng ba granules.Lebelo la ho potoloha la thipa le ipapisitse le khatello ea ho qhibiliha 'me le ikamahanya le maemo.Sesebelisoa sa thipa ea rotary se khona ho feto-fetoha bakeng sa tlhokomelo.Ho nkela lithipa sebaka habonolo ho boloka nako ka tlhokomelo.

Sieve ea Vibration

Mesebetsi e 'meli, ho tlosa metsi le ho laola boholo, bakeng sa Sieve ea Vibration:

Ka mor'a hore metsi-ring granulating, granules li tsamaisoa ka metsi.Ka Vibration Sieve metsi a phalla hole 'me granules e lula bakeng sa mohato o mong.

Boholo ba li-granules tse laoloang ke sefefo sa vibrate li tla ntšoa ka likotoana tse nyane haholo kapa tse kholo haholo.Li-granules feela, tse lumellanang le tlhoko ea boholo li tla isoa silo ea polokelo ka moea.

Ho omisa System

Bakeng sa ho omisa li-granules, mohopolo oa ho omisa centrifuge le oa ho tsamaisa moea o sebelisoa.Li-Granules li tla tsamaisoa ka moea ka har'a silo ea polokelo 'me mongobo o tla ba ka tlase ho 1%.

Silo ea polokelo

Li-Granules tsa ho qetela li tla bolokoa ka silo.Ho ipapisitsoe le tlhokeho, ho ka sebelisoa mokhoa oa ho beha leihlo le oa boima ba marang-rang.