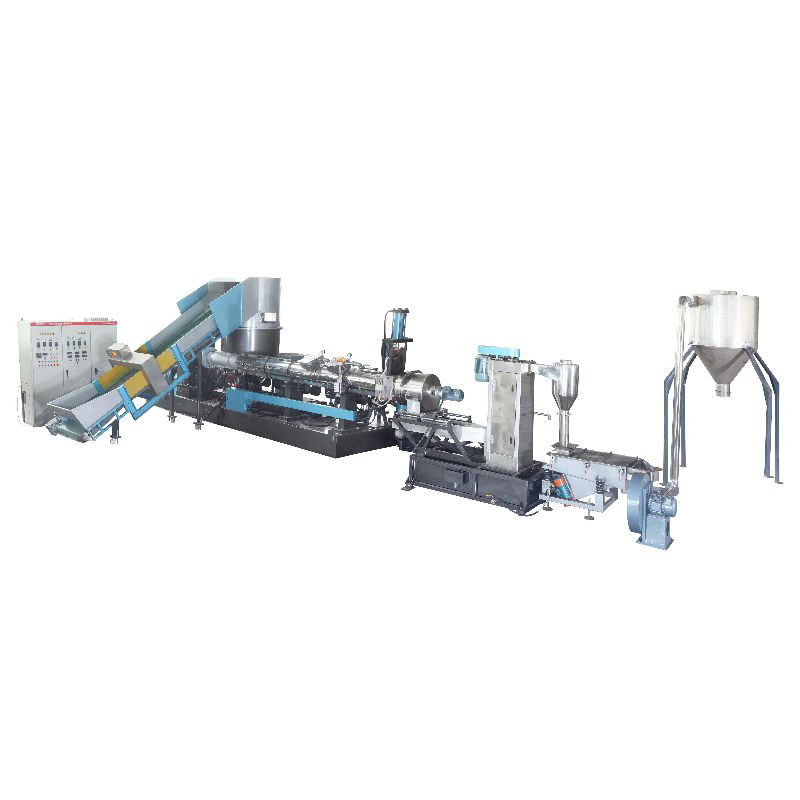

LB-Metsi Ring Granulating Line

Ha ho bapisoa le mohala oa granulating ka tlas'a metsi.

Ha ho bapisoa le granulating e ka tlas'a metsi, li-pellets li khaola sefahlehong sa moea.

Melemo ea ho etsa pelletizing ea metsi e bontšitsoe ka tlase.

➢ Monyetla o fokolang oa ho ba le serame

➢ Tsamaiso ea taolo e sa rarahanang

➢ Tšebeliso e fokolang ea matla ha u seha thipa

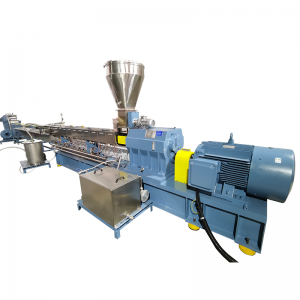

Ha ho bapisoa le mohala oa granulating oa strand

Ha ho bapisoa le granulating ea strand cutting, seha sa li-pellets se etsahala sebakeng sa polymer e qhibilihisitsoeng. Melemo ea ho etsa pelletizing ea metsi e bontšitsoe ka tlase.

➢ Ho hlokahala sebaka se senyane sa fatše

➢ Lehare la ho rema le theko e tlase

➢ Matla a fokolang

➢ Ha ho khoele e robehileng

Extruder → Ho Seha Lesale la Metsi → Sieve e sisinyehang → Sekoahelo sa metsi → Mokotla oa Pokello

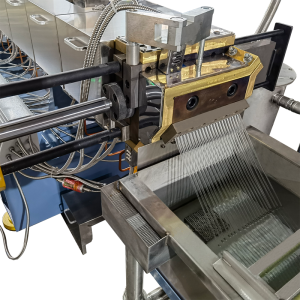

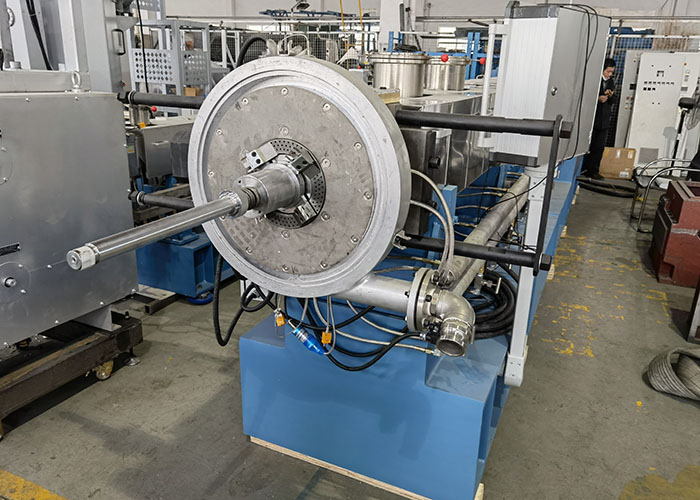

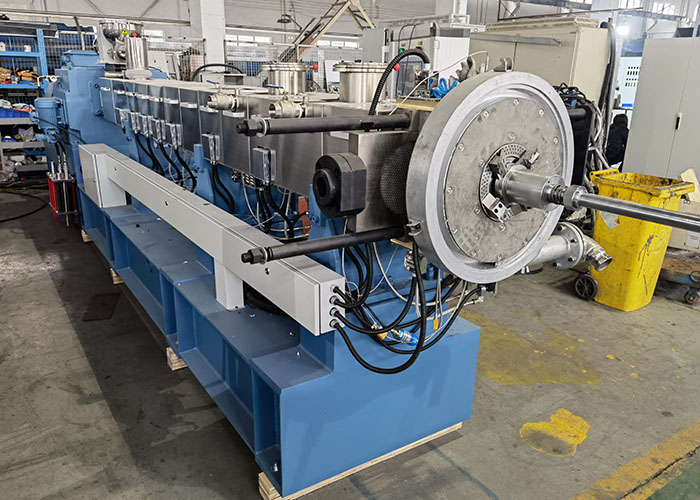

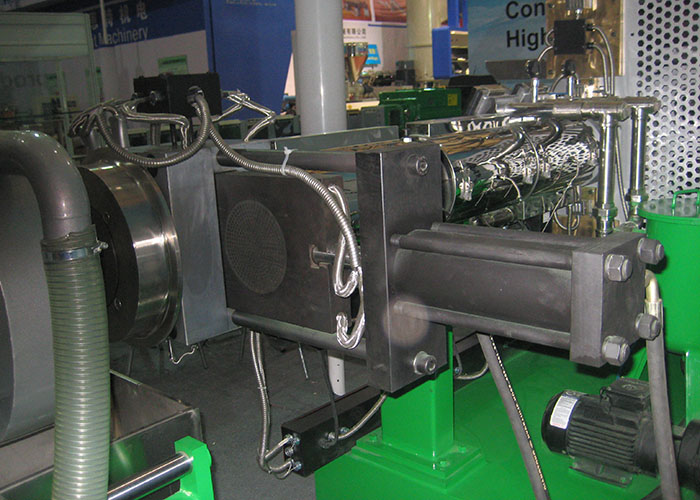

Metsi ring granulating line ke ea khopolo ea hot cut pelletizing mokhoa. Polymer e tsoa extruder e fetela lefung la annular. Sefahlehong sa lefu, polima e entsoeng ka ho qhibilihisoa e tla khaoloa ka mahare a tenyetsehang moeeng. Ka mor'a ho khaola, li-pellets tse qhibilihisitsoeng li lahleloa ka har'a selikalikoe sa metsi a oelang. Ka metsing li-pellets lia pholile ebe li tsamaisoa. Boemo ba ho itšeha, bo pholileng le ba ho tsamaisa bo hlalosa mekhoa e fapaneng ea pelletizing le ho lahla lisebelisoa tse ikhethang tsa pelletizing.

Sisteme ea ring ring granulating e hlahisa li-pellets tse chitja empa tse bataletseng tse nang le sebopeho sa matlapa a aspirin a tšoanang. Ke ka lebaka la mokhoa o khethehileng oa ho itšeha.

Ha polymer e tsoa likoti tse ngata, lithipa tse pota-potileng li khaola polymer ebe li lahlela ka ntle ka kamoreng ea selikalikoe sa metsi. Metsi a pholisa li-pellets ebe a li isa ho sefero sa sieve ho lekola boleng ba li-pellets. Ke li-pellets tse nang le boholo bo boletsoeng feela tse ka isoang se omisang se bohareng bakeng sa ho omisoa. Ho ea ka sebopeho sa polymer, mokhoa oa ho pholisa o ka ntlafatsoa.

➢ Extruder

➢ Ho Seha lesale la Metsi

➢ Sieve e sisinyehang

➢ Dehydrator

➢ Pokello Mokotla

➢ Fetola skrineng

➢ Mebala ea lisebelisoa

Die face cutter nosetsang pelletizing

Lefu la sefahleho le pelletizing

Granulating ka ho seha sefahleho

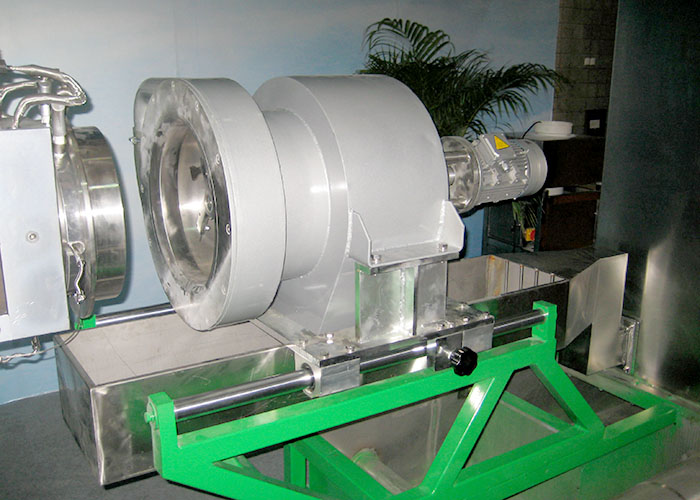

Hydraulic screen changer pellectizing WR

tse peli sethaleng extrusion metsi reng pelletizing

Kamore ea pelletizing ea metsi